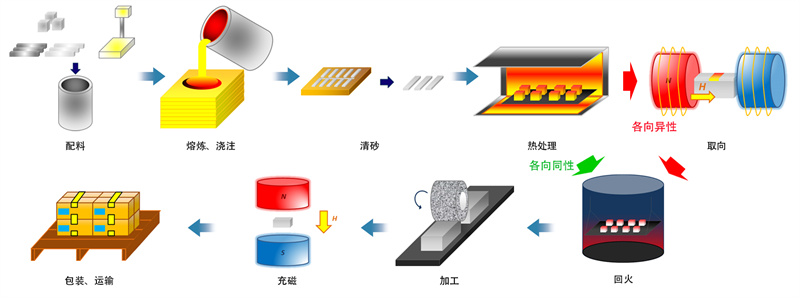

The main raw materials for sintered ferrite include BaFe12O19 and SrFe12O19, which are classified into isotropic and heterorhombic magnets based on the orientation of the magnetic crystals. Due to its low price and moderate magnetic properties, it has become the most widely used type of magnet. Chemical composition manufactured by powder metallurgy method: Ba/Sr 0.6 Fe2O3.

The annual production of sintered ferrite reaches over 300 tons. Ferrite magnets are made by ceramic technology, with a relatively hard texture and are also brittle materials. Due to their excellent temperature resistance and low price, ferrite magnets have become the most widely used permanent magnets.

Chemical composition manufactured by powder metallurgy method: Ba/Sr 0.6 Fe2O3

Curie temperature: 450 degrees

Maximum working temperature: 250 degrees Celsius

Hardness: 480-580Hv

Density: 4.8-4.9 g/cm3

Performance: Same sex (Y10)

Heterogeneity (Y25 Y30 Y35 Y30BH)