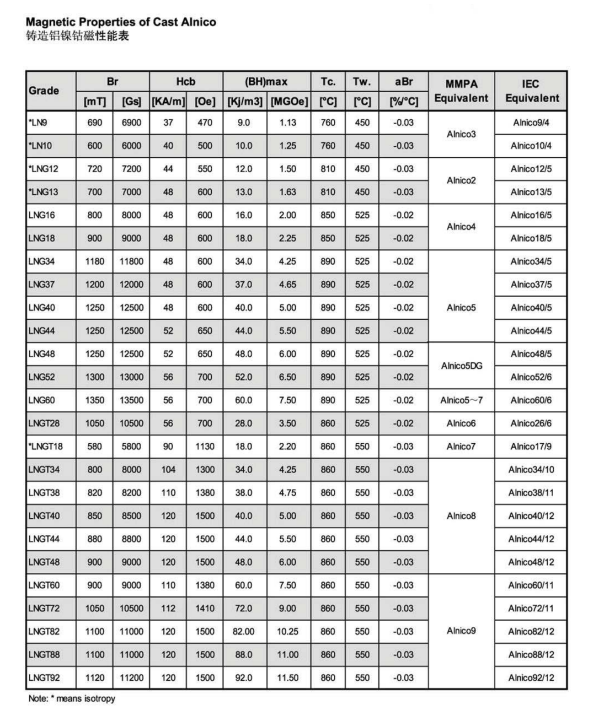

Before the emergence of rare earth permanent magnet materials, aluminum nickel cobalt magnets were widely used in the field of permanent magnet applications due to their high B value. Aluminum nickel cobalt magnets are currently mainly produced using casting processing technology, known as cast aluminum nickel cobalt magnets. The production process of casting technology involves first melting raw materials with different compositions into metallic liquids and pouring them into sand molds, followed by heat treatment, cooling, and tempering of the blank. The hard magnetism of aluminum nickel cobalt magnets originates from a two-phase nanocomposite structure composed of ferromagnetic FeCo rich phase and non magnetic AlNi rich phase formed by high-temperature uniform amplitude modulation decomposition. The FeCo phase has the highest saturation magnetization intensity and high Curie temperature at present, but the magnetic crystal anisotropy is very low and insufficient to induce strong coercivity. Due to the dependence of magnetic properties on the different saturation magnetization intensities of the two phases and the shape anisotropy of the ferromagnetic phase, in order to achieve high coercivity and remanence, aluminum nickel cobalt alloys must have reasonably oriented columnar crystals and high magnetic anisotropy. The Curie temperature of aluminum nickel cobalt magnets can reach 850 ℃, possessing excellent temperature resistance, high temperature stability, and corrosion resistance. Currently, they are still widely used in the automotive industry, instrumentation, electroacoustics, teaching, aerospace, and military fields.

Aluminum nickel cobalt permanent magnet materials have low coercivity and are prone to demagnetization due to factors such as reverse magnetic field impact, vibration, and iron contact. Therefore, attention should be paid to aluminum nickel cobalt magnets during transportation and equipment, and they should not be placed relative to the same pole