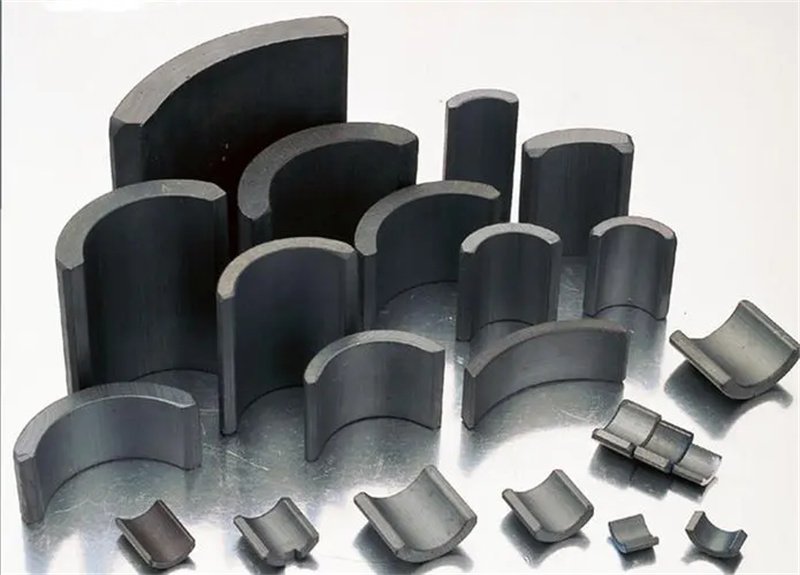

Sintered ferrite magnets were discovered in the 1930s. As a non-metallic permanent magnet material, the production process and product appearance of sintered ferrite are very similar to ceramic products, so it is also known as magnetic ceramics. Sintered ferrite has a low cost and excellent corrosion and high temperature resistance, with a maximum operating temperature of 250 ℃. Sintered ferrite mainly consists of two types: barium ferrite (BaO.6Fe2O3) and strontium ferrite (SrO.6Fe2O3). Due to its very cheap raw material price and simple production process, the finished product price is low. Its performance is moderate, its coercive force is large, and its anti demagnetization ability is strong. It is currently the most widely used permanent magnet material, mainly used in permanent magnet motors, horns, adsorption products, and toys.

The conventional performance of ferrite series products is Br: 2.0-4.3KGS, commonly used grades are Y30, Y30H, Y33, and Y35. The minimum production and processing size is L2 * W2 * T1 mm, and the maximum is L200 * W150 * T25.4 mm. The working temperature is -40 ℃ -+250 ℃, with low cost and low price; Non rusting。

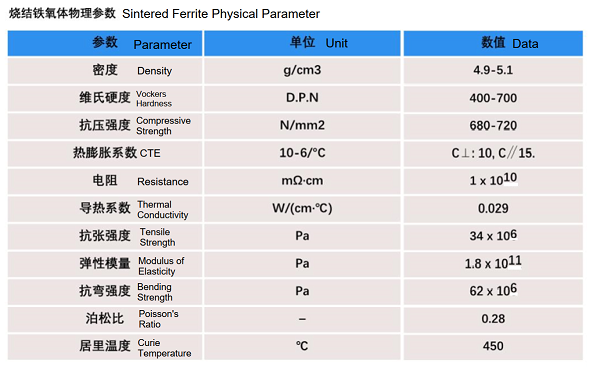

Magnetic Property Table of Sintered Ferrite

*The data in the magnetic performance table is based on room temperature measurement;

*The maximum working temperature of the magnet is influenced by both the length to diameter ratio of the magnet and other environmental factors.